Author Archive

Kitchen Renovation – Moving to Open Concept

This is part two of a series.

For part one, read Kitchen Renovation – Introduction and Footings.

The previous installment dealt with the building a new footing to support the interior end of the beam. When I last left you, I had posted a picture of wet concrete in a hole. As luck would have it, that wet concrete soon became dry, hard concrete. I watered it a couple of times to help it cure, and waited the prescribed 5 days (warm weather) curing time before loading it. Installing the posts was relatively simple. Cut 2x4s to length, hammer them into the bracket, and bolt them together. Well, it should have been simple. The problem was that 5 2x4s makes a post 7 1/2 inches. I had a stud that I really didn’t want to demolish at about 16 inches on either side. My drill, with a bit long enough to penetrate the post, was just too big to fit in that stud bay. The idea occurred to me that I could use a shorter bit, and by drilling the holes with absolute perfection, have them meet somewhere in the middle. However, that involves more precision than I am capable of; so I nixed that idea right off the bat. I ended up using a short, 3/8 spade bit to start the hole, and when I had gone in a couple of inches, stuck the long bit in the hole, wiggled my drill onto the long bit, and using some severe bodily contortions, managed to tighten the chuck. Then I finished drilling.

Now that the holes were drilled, it should have been a simple matter of slipping the bolts in and tightening the nuts. Not quite. There was a new problem. An 8-inch carriage bolt doesn’t quite make it through 7 1/2 inches of post when the 2x4s aren’t exactly tight together. I grabbed a couple of bar clamps and tried to move everything, but it just didn’t work. Road Trip! Off to the the blue store! At the blue store, I bought a ten inch bolt. I stuck it in, and nutted it tight, and everything came together tightly — tight enough that the next hole now took the 8 inch. Working up, I pulled the post together, and when I was done, took the ten-incher out and replaced it with and 8. I’m sure I could have returned the long bolt, but I had used it, and decided not to.

I installed a bit of blocking at the top, used structural screws to the header, and 10d nails into the bracket at the bottom. Once everything was done, it felt really solid. I’m not a structural engineer, but sometimes you can just tell that something won’t fall down. This won’t. Unfortunately, I was rather neglectful in the camera department, so all I have is a picture of the top of the post.

Next Step: Prepare for the post at the other end.

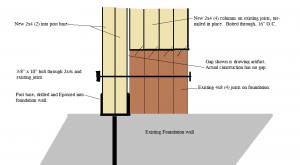

This one should have been simpler. I had a lot more room to work, having cleared out a couple feet of plaster on either side. The plan called for a single 8″ bracket, drilled into and epoxied to the top of the foundation wall. I had a sneaking suspicion that the foundation wall might have been hollow block, which would have required me to fill a couple of courses with concrete before mounting the bracket. Luckily, I was wrong. It was a solid poured foundation and it was wide enough for full bearing. Simple! All I need to do is drill and slip in my bracket. What I didn’t consider, and neither did my engineer, was that all those joists had to end up somewhere. In particular, the 2×8 double joist that was supporting the existing wall would probably be resting on the foundation wall right where I wanted to put my post! There was a third joist a couple inches away, and the space between was filled another bit of 2×8. So I opened up my finest drafting tool (MSPaint) and put together a quick sketch to email to the engineer:

That email was sent off, and my wife and I went out to a friends for 1 pound striploins, many kilos of wine and several of Fidel’s finest exports. The engineer got back the next day and approved my revision. Road Trip! This time, to the orange store, which rents tools. I rented a concrete drill and bought a tube of concrete epoxy. It took about 3 minutes out of a 4 hour rental to drill the hole. I cleaned the hole out with the shop vac, squeezed in the tube of epoxy, and stuck the base in. I quit there, figuring we’d put the post up on beam day. Besides, I had a whole lot more work to do.

Demolition:

Once again we enter the realm of lower skilled labour. My contractor is booked solid over the summer, and can only give me a day here and there for jobs that I really need him for. Swinging a hammer at old plaster walls isn’t a valuable use of his skills. So I did it myself. First, I put 6 mil poly and duct tape over every door in the house. I had learned from the small amount of demolition that I had already done for the front post, that dust gets everywhere. Turns out I needn’t have bothered. Dust got everywhere anyways. I did have the foresight to put big shipping bags over all the furniture that was too big to move out, and laid the 6-mil over the wood floor. Then I spent two days swinging a sledge, prying and reciprocating away the plaster walls. Not fun work, but also not work I want to pay top dollar for. A second person would have been useful to make trips to the dumpster, but I didn’t want my spouse becoming concerned over the mess I was creating. The only point of interest is that plaster is messy, and some genius thought it would be a brilliant idea to put wire mesh on ever corner, both inside and outside, nailed about every 2 inches. I suppose it was meant to last, and it did last for 50 years, but I wanted it to no longer last. I also ran into something the previous owner had done himself. At one point he had installed some off the shelf cabinetry, and added a couple more cabinets than the original builder had. This meant that the bulkheads didn’t quite match up. So he boxed them out with plywood. The only problem was that he was a frugal man. The type of penny-pinching gentleman that saves every screw he has ever removed in a jar. Well, he used those recycled treasures on this project. It took five different screwdrivers to pull them out: two sizes of Phillips, red and green Robertson and a slot. I saved those screws, and will use them to install something just before I sell the house. He actually did a good job of it. Everything was tight and square, and there was no room to squeeze in my reciprocating saw with a metal blade to cut them off.

At some point in there, my brother-in-law and his wife came over to help Anna pack up the cabinetry, and destroy any cabinetry that we could get away without. I also made some trips to the specialty lumber yard to order parts. I needed a couple of big nasty metal brackets to connect the beam to the posts. The load should be bearing down on the posts vertically, but we need something that can handle a bit of torque or the whole house collapses like this: / /. I also needed to order the beam, which was 4 plies of 16 inch by 1 3/4 inch LVL. The parts I needed, while standard in the catalogue, are actually made to order. This meant some delays, but the Simpson Strong Tie plant is only a 15 minute drive from my place, so I saved some time by picking them up rather than waiting for delivery. I also went to the bolt specialty store to pick up big 3/4 inch by 8 inch bolts at 8 bucks a piece.

Also somewhere in there, I spent a day and a half moving electrical circuits away from the wall to be demolished. Unfortunately, the orange store did not have wire stretchers available for rent, so it involved purchasing junction boxes to put in the basement drop ceiling or attic for splicing purposes. Only three orange/blue trips. Managed to snag a 20 m roll of 14/2 off of my next door neighbour who literally just happened to be carrying it out of the house to my bin (with my permission), as she was cleaning up her late husbands workbench. The fun work begins:

Wiht all the prep done, it’s now that most joyous of days! Beam Day! My contractor, Adriano and his buddy Franky showed up, with a truckload of tools, when they said they would, with a cup of Tim Horton’s each. On time and pre-coffeed. These are responsible contractors. They took 15 minutes to look at my plans, look at my parts, and took off to the orange store to buy big honking drill bits. Half an hour later, they were back, ready to work.

The first thing we did was install the post at the front, and mount one of the big ECC brackets. Then more of the same at the other end. IMPORTANT: Everything takes longer than you expect. Cutting, drilling and bolting 5 2x4s together should only take 10 minutes. Wrong. It’s more like 30. Then drill 2 8-inch by 3/4 inch holes for the bracket bolts. About 15 minutes each. Between Adriano’s drill, Franky’s drill and my drill, we managed to not heat them up too much. Adriano did one end, Franky the other, and I ran around and did what I was told without getting in the way. Once the post and brackets were up, it was time to install the beam.

We live in a back split, and are very fortunate (for this job) to have fantastic access to the the attic. Through the wall — not the ceiling. But, even with that, there was no way we were going to be able to manouevre a 23-foot long beam to that access door. Particularly since we only had 20 feet to the back of the house. Adriano went into the kids’ room, and took out a window. Something I never would have had the courage to do. (For fear of breaking the glass or slicing my hand off.) Franky and Adriano fed the beam segments up to the second floor window, while I grabbed and got it into the house to a balance point. Then I could hold it while the guys ran upstairs to feed it in the rest of the way. The first three segments went in easily, the fourth required a bit of “encouragement”. But we squeezed them into the brackets. We now had 4 plies in the brackets — and it was only 10:30. This job would be done by noon! Franky screwed a 2×6 across the joists parallel to the beam so we could use a pry-bar to straighten the beam, and temporarily screw it the the joists to keep it straight. (Important: do this before bolting to the brackets.)

All that was left was to drill 8 3/4 inch holes, 24 1/2 inch holes, bolt everything in, and nail up the joist hangers. That took another 4 hours. Plus a trip to the blue store for more nuts and nails. At 2:30, it was time to test our creation. Franky and Adriano went at the stud wall with sledges and pry-bars and got rid of the of the offending lumber while I ran back and forth to the dumpster. At 3:15, there was a mass rush with brooms, garbage cans and the shop vac, while we fought over the ownership of tools. Actually, sorting out tools was easy. I had designated 3 areas beforehand so that each person had their own storage. Other than a couple of drill and impact bits that we were exchanging freely, everyone respected the zones.

3:45, beer on the back patio, while I counted money out to the boys. They earned every penny. There was no way I could have done this job with a couple of unskilled buddies and a case of beer.

The Money Shot!

Anna was thrilled when she came home. We had finally achieved the open concept that we wanted. Well worth the effort.

The question I know you all have is “Was he properly attired during all this work?” I’ll leave you with this photo, salt stains and all:

Next Up: Flooring, Kitchen and more demo.

Kitchen Renovation – Introduction and Footings.

Lifestyles have changed. In a 1950s Leave It to Beaver world, urban people had very clearly defined roles. Dad would entertain the guests while Mom hid in the kitchen preparing a meal. Design reflected that. Kitchens were viewed as utilitarian areas in which guest were not to enter.

1960s and 70s design at least acknowledged that families would often eat in the kitchen, and more space was provided to accommodate a kitchen table.

Some time in the 80s and 90s the kitchen evolved into a more public space. Guests would gather and even help out in the preparation of a meal. The drawback was that seating was often uncomfortable.

More recently, the trend has been to open concept kitchens. This design philosophy often puts the kitchen right next to a dining/living room without a wall separating them. It allows the guests to sit comfortably on a couch, have drinks and snacks on the coffee table while still allowing interaction with the people in the kitchen working on the meal. It fits in with a more modern lifestyle.

Our house was built in the 60s. We have a 20′ x 10′ kitchen separated from the living/dining room (24′ x 14′) with a central supporting wall. We finally decided that that wall has to go.

Also on the list is updating our extremely dated cabinetry, which had been installed by the previous owner, probably from off the shelf cabinets. Hinges are going, finish is chipped. The laminate counter-top is swelling up in the humidity making it nearly impossible to open some of the drawers. Corner Cabinets require me to change into my spelunking equipment in order to find anything. We need an update.

So, the plan is:

- Remove dividing wall.

- Re-tile the floor.

- Replace the cabinetry.

- Re-wire so that we can make coffee and dry our hair at the same time. (Bath and Kitchen are on the same breaker)

- Install a fume hood (requires moving the stove) from an internal to an external wall.

- While the cabinets are gone, stud out the uninsulated exterior wall and put some pink stuff in there.

- Do a fantastic job, as cheaply as possible. Hire experts where needed, DIY where we (I) can.

We shopped out the cabinetry and designed the new kitchen ourselves. Next step. Call an engineer to figure out how to get rid of that wall.

Fortunately, the wall isn’t carrying a heavy structural load, but the ceiling joists are lapped on top of the wall, and they support the ceiling plaster, insulation above, and any light fixtures. So we can’t just knock down the wall, or the ceiling will collapse into the center of the house.

The solution is to install a beam to take the load off the wall, and then knock down the wall. The problem is that the existing stud wall carries a linearly distributed load. A beam, being supported at the ends only, will put the load onto two points. Consequently, these loads need to be tied into the foundation.

Step 1: Footing.

The post at the front of the house is relatively easy. It will rest on the foundation wall, which is (I assume), hollow construction blocks. I’ll simply need to fill them with concrete, a couple of blocks deep, and stick in some column base connectors while the concrete is still wet.

It’s the other end that’s the problem. I need to dig a new footing. The engineer specified a footing of 22″ x 26″ by 14″ inches deep, with a 15 mm @ 4″ spacing rebar grid, 2.5″ below the surface.

Now, digging is traditionally used as an example of extremely unskilled labour. “But the world needs ditch diggers too!” is often used as a rallying cry against sending everyone to university. Unskilled labour? I’m highly skilled at unskilled labour. This is right up my alley, and a job I can save money on.

So I started digging. This isn’t as easy as you think, because the floor is concrete. I made several false starts. I tried drilling holes with a masonry bit to create some break lines. It worked somewhat but was tediously slow.

Next I took out a mason’s hammer, with a pick on one end and just started whacking away at the center of the field. It was slow and tedious, but eventually I managed to break away a hole big enough for my hand. It was about 3 inches thick. Certainly not enough to support a load. I dug out some of the gravel underneath, and managed to whack away with a small sledge. Eventually, with a combination of under-digging and sledging, I got a rough opening dug. Then I used a sledge and chisel to clean up the edges. Concrete went into plastic pails, and were carried upstairs to the dumpster.

Digging out was much more difficult than I had imagined. I’m sitting on top of some of the hardest clay imaginable. In the end, I resorted to picking at it with the pointed end of the mason’s hammer, and scraping of 1″ thick layers with a hand trowel. Soon I ran into a problem. There was an old footing in my way.

This was 5″ thick, no where near enough for my engineer’s needs and just too thick for me to hack away with with the sledge or mason’s pick. Time for a trip to the rental store. I picked up a handheld demolition hammer (mini-electric-jackhammer) and went nuts on the concrete.

It also did a trick on the clay, allowing me to shovel it out rather than troweling it. Things went mighty smoothly. Fortunately, I had a nagging suspicion that there might be a clay sewer pipe in there somewhere. The last thing I wanted to do was crack it, so I went very carefully, probing with a thin rod, and hand digging around anything solid I found.

There was a clay pipe, and it was in the corner by the hammer head, about 12 inches from the surface. I did not break it. Infantry mine sweeping training comes in handy sometimes.

Next, I lined the hole with 6 mil poly, and threw an inch of gravel on top of that.

Meanwhile, my metal-working buddy was building the rebar for me. The main problem was that the engineer specified 15 mm bar, which is impossible to bend. 10 mm, I could have stuck in a vise, but 15 mm is just too much. He bent it in his massive hydraulic brake.

The rebar cage was made with 10″ legs, as per design. However the design also specified that the top of the cage should be 2.5″ from the surface. When I stuck it in the hole, It ended up 5 inches too low. In order to solve this problem, I ran a couple sticks of scrap lumber across the hole, and suspended it from them with mechanics wire. Good plan, as it allowed me to finely adjust the height.

Some time earlier, I put the call in to the inspector. In my jurisdiction (Toronto) All holes must be inspected by a city employed hole inspector before you make them not a hole anymore. This is actually a good idea. The building department’s job is to verify that you are following the plan. The only way they can tell, is if they see the hole as a hole. If it’s full of concrete, they have no way of knowing whether it is the proper depth, or if the rebar is even there.

Shortly after I wired the rebar in, the inspector showed up, looked at my plans, said “Yup, It’s a hole. You’re good to pour.”

After 7 paragraphs of my regaling you with tales of my hole emptying experience, you probably can’t handle that many of my hole filling experience. So I will be brief. 11 bags of concrete were mixed 2 at a time, carried downstairs, and dumped into the hole. A piece of scrap rebar was used to jiggle and poke it so that it got into the corners. I smoothed off the top, and inserted my column base. And my footing was done:

Next on the list: Attach the columns and smash plaster off the wall.

I’ll keep you posted.

Installing Laminate/Engineered wood Floating Floors

Recently my wife and I, being sick of Lego all over our living room, decided that it was time to finish our basement. I considered doing it myself, but really didn’t have the time, or the vehicle to haul materials in. We decided to hire a contractor (and got very lucky with a personal recommendation) to provide us with ready-to-paint drywall, and to come back later for trim and drop ceiling.

After installing the drywall and rough-ins, the contractor went off to Bahamas for a week’s pre-arranged vacation (with my deposit I presume), leaving me to install the flooring. I was left with a painted concrete floor (22′ x 15′), and lots of mopping to get the drywall mud and dust off of it.

Before he left, She Who Makes the Design Decisions and I went shopping for the flooring materials.

Our options:

Hardwood

Hardwood Flooring is a very attractive and durable solution. Typically, a board is 3/4″ thick, and comes in random lengths from 18″ to 6 or 7′. It’s a tongue and groove board, which needs to be nailed down to the sub-floor at an angle through the tongue. A special nailing tool is used to do this. However, we’re over concrete in this installation, and don’t want to go through the cost and effort of laying a 3/4″ plywood sub-floor or, more properly, dricore. So hardwood is out of the picture.

Engineered Wood

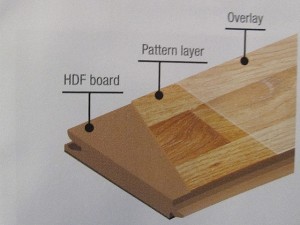

There are two basic types of engineered wood. Nail/Glue down, which is simply three plies of wood, staggered to make a tongue and groove shape like hardwood, and a final finish layer of actual hardwood. This is installed like hardwood, or it can be glued along the tongues to make a floating floor.

Alternatively, there is click-lock flooring, (pictured above) which requires no glue or nails. Typically, the base layers will be plywood or HDF (High Density Fibreboard – Think sawdust and glue pressed into a board), with a 3/16 layer of hardwood on top. This stuff is relatively easy to install, and slightly cheaper than hardwood. This is the product we were originally looking at. Engineered wood typically comes in random lengths.

Laminate

Laminate is essentially the same as Engineered, except instead of glued hardwood top layer, there is a printed surface covered in melamine. This means that a good quality laminate can be more durable than any natural wood product. Laminates that have a melamine bottom layer are also less susceptible to moisture, which makes them perfect for a basement. Furthermore, they tend to be significantly cheaper than both engineered wood and hardwood — Which is a major consideration in a basement, where there is the remote, but real, possibility of flooding resulting in a complete replacement of the flooring.

diy.stackexchange.com user Shirlock Homes makes a case against laminate here. There is a lot of merit to what he says. Laminate cannot be re-finished, and cheap laminate tends to wear our quickly, leaving you with bare HDF. Notwithstanding his expert advice, I do believe it is the correct, economical choice for a basement. Just make sure the Skil-Saw blade has stopped spinning before you put it down.

Laminates come rated AC-1 to AC-5, with 5 being the highest quality.

| Rating | Usage | |

| AC-1 | Bedrooms | |

| AC-2 | Living/Dining Rooms, Kid’s Rooms | |

| AC-3 | Hallway, Living Room, Office (rolling chairs!) | |

| AC-4 | Office, Cafe, low-traffic retail | |

| AC-5 | High traffic public areas – Retail, Banks, large offices |

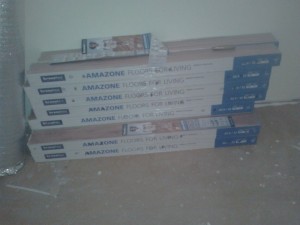

The product we ended up purchasing was AMAZONE Canadian Maple, by KRONOTEX. This is an AC-4 rated product, which means it should be more than sufficient for our basement. This product comes in fixed lengths.

Preparation

Now that we’ve selected our product, and loaded it into the job site it’s time get the prep work done.

- Ensure the floor is level, and flat. If it isn’t, you have to decide whether you want to grind down any lumps, level the floor with Self Leveling Compound, or live with some imperfection. Our floor had some variation, and we probably should have leveled it, but the cost was prohibitive. We decided to accept the imperfection.

- Remove baseboards, and undercut door trim. (Not required in this installation, as it hadn’t been installed).

- Clean the floor – This is critical. You don’t want any lumps of mud or any organic material on the concrete – this is food for mold!

- Stack your material on the wall you are going to finish LAST. Leave it there for a few days to acclimatize to the moisture level of your room.

- Lay the underlay. Some say that the underlay should run perpendicular to the flooring. However, this means that you have to do all the underlay in one go, and keep it clean while you work (an impossible task!). Since it comes in 3′ widths, I prefer to run it the length of the room, lay the flooring on top, and lay the next section when I get near the edge.

The Installation

Tools

- Mitre Saw -for cutting boards to length

- Table Saw – for ripping your final boards to the appropriate width.

- 4 x diy.stackexchange.com Carpenter’s Pencils. You’ll need one at each saw, one behind your ear, and one left on the floor near the end of the run. Beware of inferior pencils. Only the official diy pencil will work.

- 2 x Measuring tape – one in the work area, and one by the table saw.

- Undercut saw – for cutting under door trim (if necessary)

- Broom and Dustpan

- Shop Vac

- Jigsaw

Since the end of each run will require a cut, I prefer to chop my boards in the work space. This necessitates lots of cleaning and vacuuming, but saves many trips up and down the stairs. The table saw can be set up in any convenient location out of the work area, such as a nearby garage.

STOP! There’s one last bit of thinking!

One thing we need to avoid is a skinny little space left over after our final run. Since my boards were nominally 3 inches wide, I need to know how much space will be left over for my final course. Ideally, I’d love it if the final board just clicked into place leaving me a 1/4 inch of space to be covered by the skirting. THIS WILL NOT HAPPEN! The reality is that you need to rip (length cut) the final course to make it fit. We could just blindly plunge ahead and deal with that issue at the end. But, we could end up with a 3/4″ space, which will just look awful. We need to estimate this gap before we begin.

- Measure the room width as accurately as possible. You want to find a maximum and minimum width, to the 16th of an inch. See http://diy.blogoverflow.com/2011/12/secrets-of-the-tape-measure/, BMitch’s excellent post on measuring. Subtract 1/2 an inch (you need 1/4 inch gap on either side)(I ended up with 15 ft, 2 12/16 inches)

- Snap 3 or 4 boards together, and measure the width to the nearest 16th of an inch. Divide by 3 (or 4) to get the board width (3 1/16).

- Convert everything to 16ths of an inch. Room =(15 x12 + 2) x 16 + 12 = 2924 16ths. Board = 3×16 + 1 = 49 16ths.

- Divide the Room width by the board width 2924/49 = 59.67346939 (keep all significant figures)

- Subtract the integer part, and multiply by the board width (.67346939 x 49 = 33 16ths) This is more than half a board, so I’m good.

- In the event that you end up with less than a half board (lets say 15 16ths) the solution is to rip 1 inch off the tongue side of the starting boards, so that you’ll end up with an approximately 2 inch board at either side of the job.

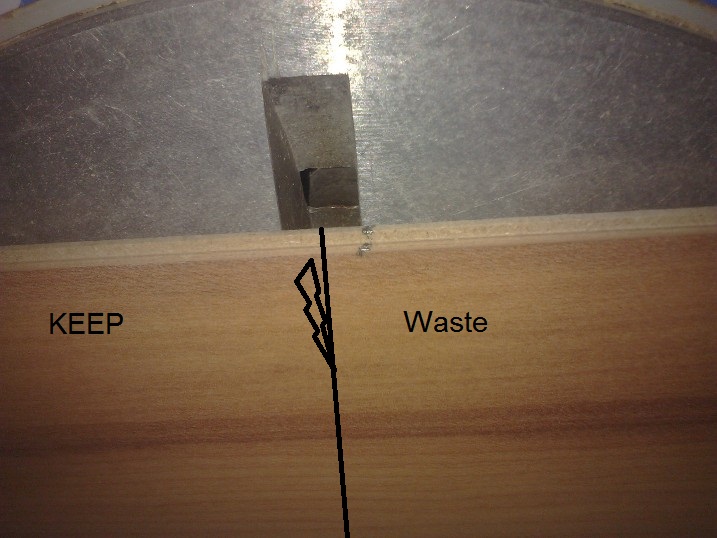

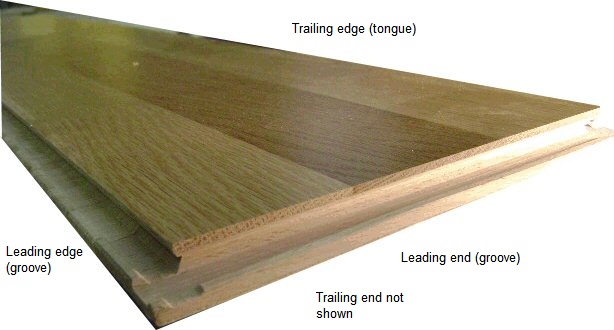

Before we get started, lets define some terminology. Unlike hardwood, you lead with the groove, and snap the tongue of the next board into it. This picture explains what I mean:

Let’s go!

Take a piece of flooring (ripped if necessary), and lay it in a corner, over your underlay, parallel to the longest wall. Remember to leave a 1/4 gap around the walls. The trailing edge, and the trailing end go up against the walls. It will move, so don’t worry.

Continue down the wall, butting the next board to the one before, and the trailing edge should click into the leading edge of the previous board. This is going to move, so again don’t worry.

When you get to the end, your piece of wood will be too long. (If you have random lengths, pick one that is significantly longer), it’s time to make our first chop.

Interlude: Cutting Boards to Length

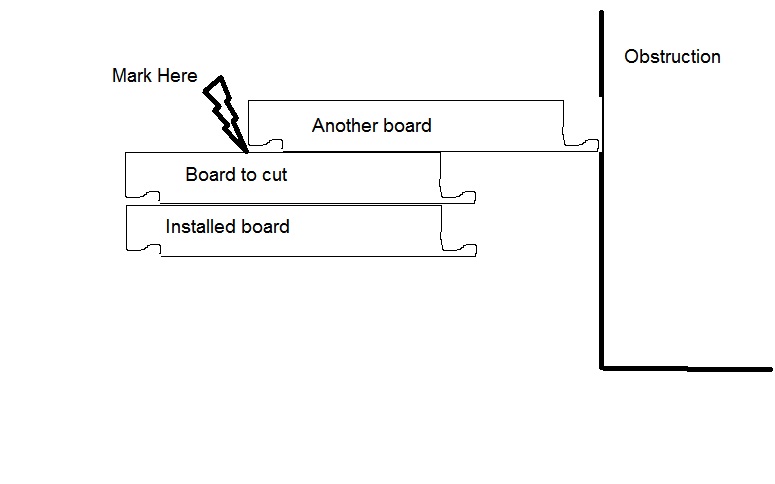

We need to cut a board to fit the remaining space AND leave a quarter inch gap. We could mess around with measuring and calculating, but I’ve figured out a better way.

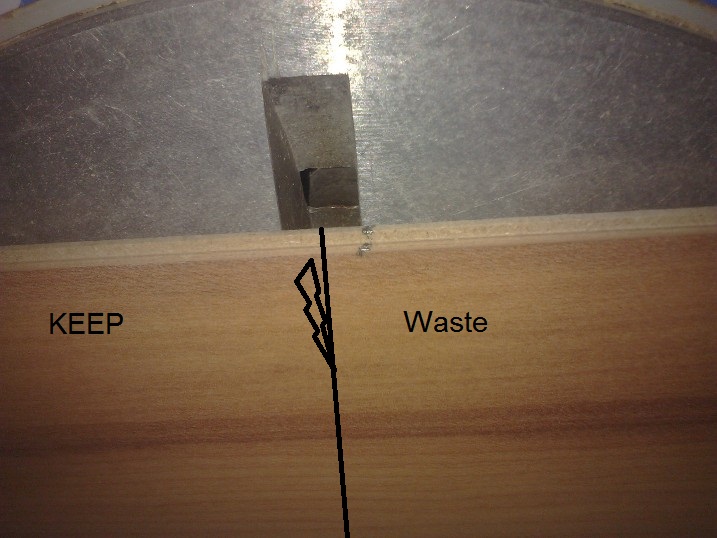

- Lay the board upside down trailing edge (the edge you want to keep!) butted tight to the wall over the last board you installed.:

- Using your diy.stackexchange.com carpenter’s pencil (as seen in the image above!), mark the tongue exactly even with the previous board. (This gives us the full length – we still need to remove 1/4 inch)

- Lay the mark on the board right on the edge of the slot of your mitre saw and cut. This should be close enough to 1/4 short of what we marked. As long as the skirting/quarter round covers the gap, we’re good.)

Carrying on…

Slip the piece marked KEEP into the end of the row. The piece marked waste, if really short can be thrown out. But! hopefully it’s pretty long, and we can use it to start the next row. If you have random lengths, pick your end piece to leave enough for the next row.

The next row is probably the most difficult. You need to slip the trailing edge of the current row into the leading edge of the previous while making sure the butt joins of the first row are perfectly aligned. If the board doesn’t slip in easily and click into place, your butt joins are misaligned OR there’s crud in the groove. I find that the corner of the trailing edge and end grooves often gets a bit munged up. It’s easy enough to remove any imperfections with your fingers, or a utility knife.

Carry on with the second row, making an end cut when necessary.

Now that everything is locked together, the third row is much easier. Notice however, that the floor is still moving. Don’t worry about it until you have 4 or 5 rows down. Then the floor should be heavy enough to hold itself in place. Just remember to check the 1/4 inch gap against the starting wall every once and a while, and slide the laid flooring around to correct it. Once you’ve got halfway, move your material from the finishing wall to a convenient location on the completed portion of the floor. This will help hold it down, and get the material out of your way.

Hopefully, you can continue on until the last course, laying a new row of underlay as required, rip a few boards at the end, and slip out for a beer. (Not Bloody Likely!) What’s likely to happen is you run into something like this:

or into a closet door, a run-out to a stairwell or some other obstacle. You’re going to have to cut.

Dealing with obstructions

You have two choices here. You can measure the distance, and cut the first board of the row so that your seam ends up in the middle of the obstruction, and make a join like this:

or you can cut out the middle of the board with the jigsaw. The trick with the second option is getting the width of the cut. Here’s how you do it:

If you do it right, your end result should look like:

Note, that this measuring technique is extremely useful for measuring the rips for your final row. Remember your 1/4 inch gap!

Another obstruction you might run into is a closet. This takes a bit of doing, but it isn’t that hard.

The problem here is that I was working left to right, and had to then work right to left in the closet, which is difficult as the material is designed to be worked in one direction. However, it is possible to clip in a piece from the rear.

When I got to the opening of the door, I cut the board out in the middle as above, and ran it to the back of the closet. I then removed this board, and put it aside for later.

I laid the floor in the closet just as if I was starting fresh, making the first board a whole board. until I got past the opening. I then removed the FIRST board, and laid the piece that I had cut out, connecting it to my closet boards. Now I’ve got something I can measure! Rip the first piece, and try to slip it in from the back. Alternatively, I could have undone the last few feet of work in the closet, and relaid it fresh, starting with the ripped piece.

The Last Row

If you’re still with me, you can probably figure it out for your self. We’ve got a gap at the end, which is too narrow for a course of boards. In an ideal world, we should be able to measure, set up our saw and rip 4 or five boards at once. This might work for you, if you can verify that the gap is a consistent width the entire length. It probably isn’t. Remember that nothing in your house is parallel or perpendicular to anything else in your house. There is error in everything constructed. You’ve got to measure each board by itself. Use the stacking technique in the dealing with obstructions section to figure out the widths.

Once you’ve ripped and installed the boards, you can reinstall the skirting boards and quarter round, or decide to leave that for another day.

Hopefully your final product will look as good as this:

Total Time: 7 hours for 330 sq. ft.

Summary:

- Do your prep work. In particular, measure accurately to avoid a 1 inch rip at the end.

- Keep your work area clean. Dust and bits of cardboard packaging in the grooves make the job tough.

- Slow and steady wins the race. You can’t rush this.

- Deal with obstructions properly. Measure twice cut once.

- This really is a one person job. Helpers get in the way. Although an extra hand on the broom or clearing packaging is appreciated if someone pops in for a few minutes.

- This job is hell on the knees and back. You will need a liberal application of “muscle relaxants” after completion. Don’t make any plans for the evening.

- Only @aarthi approved diy.stackexchange.com Carpenters Pencils will do. To get some, write a blog post on a project, or a tool review, and @aarthi will send you some! Talk to @tester101 about your blog account.

Hanging Shelves

This is a continuation of my previous blog post.

This blog posting was originally written in 2008 for a friend of mine who was unable to perform simple repair tasks around her house. The original purpose was to assist her in hanging shelves on her wall. It is intended for those people who know that the flat end of the nail is the end you hit with the shoe, and that butter knives make acceptable screwdrivers.

L- Bracket Shelves

So, let’s look at the simplest type of shelf to put up: Basically, we’re talking about a plank of wood, and two L-brackets. It’s not the prettiest type of shelf, but it is cheap and functional. I actually don’t recommend this type of shelving for all but the most utilitarian installations. BUT, this installation will demonstrate the essential properties of shelviness — The shelf is level, and it is strong enough for most small loads. The techniques used here are also applicable to hanging curtain rods and small bathroom shelves. My general principle is that you can’t possibly measure and pencil out the installation accurately. (See Golden and Silver rules in my previous article.) So we’re going to do this in a way that doesn’t require that.

Materials:

1 shelf 2 brackets 1 pencil 1 carpenter’s square (It’s called a square, but it might be triangular in shape) 8-10 screws – Often these will come with the brackets. You’re probably best off to get some longer wood screws for the wall mounting. Keep in mind that your drywall can be up to 3/4 of an inch thick, and we’ll want at least an inch in the wood. I’d get 2 inch wood screws with a countersunk head. 1 drill drill bits 1 level 1 helper – these can usually be found by offering a beer.

Step 1: Hold the shelf up to the wall where you want it to go. Take a pencil and mark the height about 6 inches in from one end. This is just a rough guide for now. You don’t need to mark the entire length.

Step 2: Find the studs. This can be tricky, but if you’re going to use it for books, then you need to find a stud. Sometimesyou can find them by tapping lightly with a small hammer and listening for a spot where the echo turns into a thud (a doctor’s knee tapper would be ideal). This might work if you have drywall and wood studs, but plaster and lathe seems to make the same sound no matter where you tap it. Borrow an electronic stud finder from a friend. I you can’t get a stud finder, then we have to resort to destructive testing. Find a long skinny nail, such as a two inch finishing nail. Bang it in where you think there might be a stud. Move over an inch and a half an try again. Repeat until you know you’ve hit wood. The problem with this technique is that you will be left with a plaster repair and paint touch up when done, but it is reliable.

Once you’ve found one stud, the other is easy. Studs are usually placed every 16 inches. Just measure over and tap again. Mark the studs with vertical pencil marks (lightly – You’ll want to wash it off later). I like a couple of ticks at the edge, and a longer line down the middle. .|. For shelves, it is imperative that you find a stud. Drywall plugs won’t support the weight of books.

Step 3: Place the board back up, center it on the studs, so there’s an even overhang on each end and mark on the board, ONE side where the stud line meets the board (ideally about 6 inches in from the end). Take the board down, and on the underside using a square (which is usually triangle shaped) mark the perpendicular right across the board.

Step 4: Balance the board on its back on a good solid flat surface so that the edge that will contact the wall is against the floor. Do your best to keep it straight up and down. Put one of the brackets against the board and the floor and press so the flex is taken out of the bracket, and the screw holes are directly over the line. Have your helper mark the screw holes on the board. (That 2 inch finishing nail works great! Stick it in the center of the hole and tap lightly with a hammer).

Step 5: Drill out the screw holes. The diameter of the drill bit should be slightly smaller than the inner diameter of the screw (The solid part inside the threads.) Attach the bracket to the board. NOTE: Your drill will usually tend to “Walk” away from the marked point when you start it up — particularly on hard materials. This is less than ideal. You can take a nail, and bang a dimple over the pencil mark to stop this. The small hole will grab the point of the bit and stop it from walking.

Step 6: Mount the shelf, lining it up with your previous marks, and mark only the upper screw hole where it meets the wall and stud. Drill. You can use a small bit, as you’re going into a 2×4 here. Screw in the upper hole, and lightly put a screw in. You’ll be taking it out in a minute.

At this stage, you’ve got one bracket, tightly secured to the board, and loosely secured to the wall.

Step 7: Level the shelf. This is fairly easy, as you have one fixed end to pivot around. Just move the other end up and down until the level bubble is centered. Mark the stud line on the board and mark the underside of the shelf against the wall (As per Step 3). Take the shelf down, and repeat 3-7 for the other bracket, and finally drive home the actual screws that will hold it up.

Hanging Shelves with Vertical Rails and Brackets

Shelves with vertical rails are a relatively cheap solution. They consist of two or three vertical rails that are screwed directly to the wall. Brackets clip into the rails, and the shelves lay across the brackets.

The IKEA version is functional, but rather pricey for what it is. You can buy the parts at any hardware store and build your own to fit your space. If you go this route, Laminated MDF is a good choice for the actual shelves as it is pretty stiff. However, it can be unattractive. Another choice is to buy some 12 inch pine boards at your local lumber yard. They will cut it to length for you there, so have the measurements ready. You can then stain or paint it yourself.

Canadian Tire has a two shelf 24″ kit for 19.99, (White, melamine laminated MDF) so this would be a cheap starter. You could replace the shelves later.

These instructions are written assuming the DIY route. If you buy a package, then some of the cutting and measuring can be eliminated.

Design and materials.

Typically, 3/4″ lumber storing books can span 36″ without significant sagging (according to the wisdom of the internet). However, studs are 16″ apart, so 32″ is a better choice. A 4 foot shelf can be problematic. The only mounting solution is three rails at 16″ spacing or 2 at 32″, leaving 8 inches of overhang at either end. The danger is that a partially loaded shelf might flip up like a teeter totter if there is too much overhang. I’d feel better with 3.5 foot shelf, which could be mounted on two rails at 32″ spacing and 4.5″ of overhang.

Leave about 6 inches of excess rail above the top shelf and below the bottom. This will help distribute the load nicely over the wall.

You might wish to take a measuring tape and a piece of chalk and actually draw your shelving on the wall before you head out to the store. It really helps to visualize the solution. (hint – find the studs now, as they are where the rails go.)

Materials: 2 or 3 rails. Buy them pre-cut. They typically come in 24, 30 and 60 inch lengths. 2 or 3 brackets for each shelf. Shelves. Screws. Drill, Bits. Driver. Helper. Level. Plumb Bob and chalk line (optional) Chairs or step ladder.

Getting to work:

Step 1: Preliminary Reconnaissance Figure out where you want the shelves to go, and hold up the upper one to the wall. Mark the end points so you know your boundaries. Now you need to find the studs. I’ve discussed that in the L-Bracket shelf instructions, so I’ll leave you to it. However, if you are hanging a 24 inch shelf on 16 inch studs, that leaves 4 inches of overhang at either side. You might have to move your ideal location over a bit so that the shelf is centered on the studs. Once you’ve found the studs, hang a chalk line and mark it. Alternatively, mark it with pencil in several locations and use the edge of a shelf, or even the rail itself to mark the studs.

Step 2: Like before, we’re going to do one side first, and then match the other to it. Figure out where the top of the rail needs to go. Mark the top screw hole, and drill. Again, the drill bit should be smaller than the screw. Lightly screw the rail to the wall using the top hole only. Let the rail hang loosely. Hopefully the rail will hang exactly over the line you drew earlier. If not, you have to decide now which vertical you want (i.e. Your studs aren’t vertical, or the gravity works differently in your house) . The likelyhood is that neither is correct. Check with the level if you need to. Once you are satisfied, mark the remaining screw holes. Tip: You probably won’t be able to get a pencil to touch the wall through the rail. Use a skinny nail, and give it a light tap with a hammer to mark the wall. Draw a circle around the marks so you can find them.

Step 3: Mount the first rail. Take out the single top screw, and take the rail down. Now drill out the holes you just marked. Put the rail back up, and screw the screws in until they are just tight. It’s best to do the top and bottom first, ensuring everything is lined up straight. Then fill in the middle ones.

Step 4: Mark the other rail CRITICAL STEP The first rail was easy, as we didn’t really care too much about the vertical placement. The second rail has to match the first exactly. There is really very little wiggle room here. If the rails are mis-aligned, the shelves will be sloping, which is not one of the properties of shelviness we desire. This can actually be very tricky. The obvious solution would be to measure down from the ceiling. THIS WOULD BE WRONG. Remember, everything in your house is wrong. There are no straight lines and no 90 degree corners in your house, and every time you pull out a tape, you’re introducing error into the equation. One might be tempted to try and line up the second rail by partially assembling the brackets and temporarily mounting a shelf using the brackets and a shelf. In my experience, this is more trouble than it’s worth. It might be a workable idea when you have 3 pairs of hands, but then communications between those hands becomes an issue. Hopefully you’ve bought pre-cut rails, so you can use this technique: Have your helper put a shelf, or other rigid straight body right across the top of the mounted rail. Make sure that it is flush to the wall and the rail. Now, using the level, level the shelf and mark the underside where it meets the other stud line. The person marking should be the person adjusting and watching the level. Now you can mount the second rail with its top just ever so slightly above this pencil line. (Keep in mind that the pencil mark takes a bit of space.) Follow step 2 and 3 for the second rail. It’s a good idea to measure the spacing at the top and bottom to make sure they are parallel. If you’re within an 1/8th of an inch, you’re probably ok.

Step 5: Mount the middle rail (if required) If you need a center rail you can mark the top just by balancing a shelf across the existing rails and matching the rail to it.

Step 6: Tighten screws another half turn. If you over tighten, you’ll damage the wood underneath, and the screw might pull out.

Step 7: Attach the shelves. This is a pretty straightforward task.

We’ve gone through some fairly basic tasks which demonstrate a few principles. The first and foremost being that measurement is rife with errors. What I have attempted to show is that we can do a whole lot of quality work while keeping this error prone task to a minimum. Also notice that we’re screwing directly into the studs here. That is why there are no drywall anchors. While anchors do carry significant weight, they’re not strong enough for shelving that is going to carry anything more than decorative items — and you’ll be wanting nicer shelves for that task.

General Tips for Household Repairs.

This blog posting was originally written in 2008 for a friend of mine who was unable to perform simple repair tasks around her house. The original purpose was to assist her in hanging shelves on her wall. I will post the follow-ups soon. It is intended for those people who know that the flat end of the nail is the end you hit with the shoe, and that butter knives make acceptable screwdrivers.

Golden Rule:

Measure twice, cut once.

Silver Rule:

You can’t measure anything accurately. Therefore, Always dry-fit the project and make sure it fits.

or

Reality often has it wrong, so you have to be wrong in the right way to make things work.

If you watch a professional, you’ll see that they’re constantly dry-fitting, adjusting and re-fitting pieces. However, you can reduce the number of measure/cut cycles you go through by reading BMitch’s excellent blog post on tape measures.

General tips:

Do I have Plaster or Drywall?

There are several types of plaster you might run across in homes built in the 1960’s and earlier. The most common type is Plaster and Lath. Lath is thin strips of wood nailed up to the studs in a diagonal pattern. Then Plaster is spread on top to make a smooth finish. In really old houses, the plaster contained horsehair to give it some tensile strength. The only advantage of a plaster wall is that you don’t need to find a stud for light loads — the lathe is everywhere. The major disadvantage of plaster is that it is brittle, and cracks propagate quickly. Put a piece of tape over the plaster before banging in a nail, and you can reduce much of the cracking.

Drywall is factory made gypsum plaster sandwiched between two sheets of thick paper. It comes in sheets (4 x8′ or longer) and is screwed directly to the studs. It is taped together with paper tape and a plaster like compound called Drywall Compound (or MUD) to hide the joins. It’s a lot faster to put up, and relatively easy to repair. However, It doesn’t support much weight at all. Usually light loads will be attached with a plastic drywall plug to spread out the downwards force so that your nail or screw doesn’t pull down the wall, opening a crack like a zipper would.

For houses built in the 50’s and 60’s you may come across a solution that is the worst of both worlds: Gypsum Lathe and plaster. Gypsum lathe is essentially thin sheets of drywall screwed to the studs. Then it was plastered over as if it were wood lathe. The major problem is you still get the brittleness of plaster without the additional support of wood lathe. Furthermore, the gypsum came in large sheets, so that the plaster doesn’t flow in behind and lock like it does with wood lathe. This can lead to de-lamination of the layers, particularly in cases of water damage.

ALWAYS drill before screwing.

ALWAYS! No exceptions. Select a bit so that the shaft of the screw is about the same size as the bits. This will remove the material that you would otherwise have to push aside (with a splitting risk) while still leaving enough material for the threads to grab.

Reject all screws except the Robertson (Square head).

It is the easiest to use, and it’s your patriotic duty as a Canadian to support this superior screwing technology. The only drawback is that you have to use the correct sized driver. Robertson screws save all sorts of heart-ache and pain. The greatest advantage of the Robertson is that the screw will stay on the driver. This means that you don’t need the other hand to hold the screw. This frees up the other hand for duties like holding onto the work of holding onto dear life as the case may be. The Phillips screw was designed so that the drive would twist out of the screw head if it got too tight. This is a perfectly acceptable design decision. However, usually, we don’t want our driver to torque out of the screw. (Exception: Drywall screws)

The job will take twice as long as you anticipate.

ALWAYS! No exceptions. Even when you take this rule into account.

Nothing in your house is built right.

There are no 90 degree corners. Nothing is flat, and parallel walls aren’t. Make no assumptions. Use a level and a plumb bob to determine horizontal and vertical.

Hanging light things on a wall

If you’re hanging something light, like a picture, or a bathroom medicine shelf, you don’t need to find a stud, you can use drywall plugs instead. Usually the package will tell you what drill bit to use (5/8 or 1/4 are pretty standard.)

Nails and screws are not interchangeable.

They each have specific uses. Other than tiny picture hangers and quarter round, you probably shouldn’t be using nails around the home.

Know your screws and what they are for:

These are the common screw types that you’ll see at the local hardware store. There are many more specialty types, but here are the basics.

Wood Screws

Wood screws are pointy, and may or may not have threads all the way to the head (usually not). Often the head has a conical profile allowing the head to be driven into the material and lay flat (or covered with a plug or wood filler.) When joining two pieces of wood together, you want the unthreaded portion of the screw to be about the same length as the thickness of the top piece of wood. This means that the threads will bite into the lower piece, and everything will pull tight together. If you were to use a drywall screw instead, it is quite likely that the screw will actually end up forcing the pieces apart slightly.

Wood screws are pointy, and may or may not have threads all the way to the head (usually not). Often the head has a conical profile allowing the head to be driven into the material and lay flat (or covered with a plug or wood filler.) When joining two pieces of wood together, you want the unthreaded portion of the screw to be about the same length as the thickness of the top piece of wood. This means that the threads will bite into the lower piece, and everything will pull tight together. If you were to use a drywall screw instead, it is quite likely that the screw will actually end up forcing the pieces apart slightly.

Sheet Metal Screw

Pointy, sometimes there’s a self-tapping notch near the point. Usually the head has a dome profile, but counter sunk does exist. Finer threading than wood screws, and the threads go all the way to the head.

Machine Screw

Dome profile. Flat point. Can take a nut or be screwed directly into a tapped hole in metal objects. (This means you have to have a threaded hole to screw into. Absolutely no good for wood)

Lag Bolt

Not actually bolts, as they don’t take a nut. Usually quite large, and rather than taking a screwdriver, they usually have a hex head. Big coarse threads, that don’t go all the way to the head. This is a screw for joining big structural lumber.

Carriage Bolt

Basically a Machine screw, with a nut. Carriage bolts tend to be big, like a lag bolt. Often the name is used interchangeably with a Machine screw. Basically, these are used to join two pieces of metal together, often with washers to allow some motion. Think Meccano, but bigger. The can also be used to join beams together. A hole of appropriate size is drilled through the material, and the bolts are tightened so that the friction between the wood pieces prevent any movement. You can see this use in many pergolas and wooden backyard play sets.

Drywall Screw

Skinny, sharp, long. Usually black or blue in colour. Use these only for putting up drywall, and nothing else. Usually only available in Phillips heads. People putting up drywall will usually buy a special tip for their drill that takes advantage of the Phillips driver’s tendency to slip out of the screw. This allows them to lightly dimple, but not break, the paper sheath. Drywall is the only application where I would recommend using a Phillips head.

Deck Screws

These look pretty similar to thicker drywall screws except that the are available in Robertson heads. They’re usually green in colour, and are treated to put up with the corrosive nastiness of pressure treated wood. If these are the only screws you have laying around, then it’s probably safe to use them for interior repairs.