THE SETTING

Our 1869 foursquare farmhouse had been renovated around 1905 to make it more “upscale and modern”. The front and back parlors were joined and a fireplace was installed. In 1999, the house again got a makeover, with new beams, plumbing, wiring, but maintaining much of the molding, windows, and style from the turn of the 20th century.

The fireplace now consisted of a painted wooden mantle and trim, with a brick façade around the firebox. The façade had been painted several times, but seemed fairly sound. It was now a dull, dark greyish green. Time for a freshening up.

DESIGN

We decided on tile, selecting an arts-and-crafts style that would have been in keeping with early 1900s décor. The 4 ¼” x 4 ¼” tiles were handmade in California. We chose field tiles (regular four sided tiles), bullnose tiles (with one sloped finished edge) and a few decorative bulls-eye tiles for accents. The tiles were about 1/2” thick and slightly irregular, with no built-in spacers.

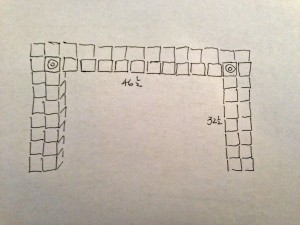

The layout worked out fortuitously. We wanted wide grout lines, often seen on arts-and-crafts projects. We also wanted decorative tiles on the inside corners where the vertical and horizontal runs met.

With the moldings closest to the façade removed, and with a careful adjustment of the grout spacing, we were able to get a pattern that gave us two columns wide on the sides and two rows deep on the horizontal section. We wanted only full tiles between the decorative corners, but the 48″ spacing between the inside edges of the firebox was a bit too wide for 10 tiles, even with 3/8″ grout. Stretching them out was not an option because the grout lines would be too wide compared to the vertical runs. So we decided to add tiles to the vertical inside edge of the firebox. This narrowed the horizontal opening by about 1½” ( the thickness of two tiles and thinset), down to an overall width of 46 1/2″ . With just a little fudging of the grout width to a hair more than 3/8” (but not quite ½”), we got a satisfactory fit of ten tiles horizontally between the bulls-eyes.

PREPARATION

Getting ready for the installation, we took a closer look at the brickwork, only to find that it was not. The sloping angle of some of the “brick” corners should have been a giveaway. This was actually stucco that had been textured and grooved to look like decorative brick.

As I begin each DIY project around our house, my wife asks “Have you ever done this before?” the unstated, but obvious worry being that I was going to serious wound myself, set the place on fire or cause a giant sinkhole to swallow up our homestead. My usual answer is a smug, silent look, implying that, beyond question, I am up to the task. But his time, I actually hadn’t done ceramic tiling before. Time to start reading, surfing the web, and asking my good old friends on diy.stackexchange.com.

While the paint on the “brick” façade was largely intact, we were a bit unsure about whether the thinset mortar used to mount the tiles would adhere well enough. A quick post on DIY brought me some great feedback. Regular contributor HerrBag suggested trying a test patch of thinset on the surface to see how well it adhered. The test showed fair (not great) adhesion with some paint peeling away and some thinset sticking pretty solidly.

Heavy tiles and some exposure to heat suggested a stronger grip was needed, so we went through a vigorous scraping of the painted surface with a wire brush to remove any loose paint. Then we did a thorough scarifying of the surface using an angle grinder with an abrasive wheel to cut grooves into the stucco.

You know how they say “preparation is more than half the task”? Well we didn’t prepare well enough for the hurricane of dust that blew through our entire house. We had taped and masked the wood of the fireplace and put down newspapers for several feet. We wore safety goggles, dust mask and gloves. Nowhere near enough protection! The grinder threw up clouds of paint and stucco dust, worst in the immediate vicinity, but the film reached upstairs bedrooms! We have since been cleaning for weeks. And with old paint there is always the risk of lead contamination. (Next time, a full plastic tent around a grinding project.)

TILE MOUNTING (Part 1)

Before beginning the actual tile mounting, we put on a skim coat of thinset to level out the variances in the stucco and give a more complete base for the tile.

Now on to the actual installation! Guided by several books on tiling and an internet sweep, we positioned a support brace at the top edge of the firebox (the bottom edge of the horizontal run). It was leveled and attached with light duty anchors and screws (it’s only temporary).

After mixing the thinset powder (having been warned away from premixed products) with a drill and mixing paddle, waiting the required slaking time (to fully absorb the water), and remixing, we slathered on the mixture, and then striated it using a notched trowel. Finally, we began setting the tile, beginning with one of the corner decorative tiles, working across to the opposite decorative tile, using spacers to guide the placement and then tweaking to get even spacing. Over the firebox, bullnose tiles are used, with the tapered edge facing down.

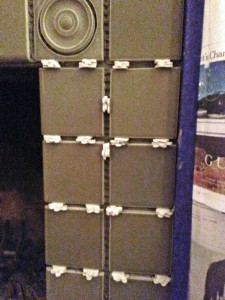

The row above then followed, finally filling in the area outside of the decorative tile, both using field tiles. Numerous spacers were used to keep the tiles in position (including additional spacers gently wedged in where additional support or a slightly wider gap was needed). Tiles are tapped into place with a rubber mallet to seat them firmly. If precise leveling were needed, a tapping block, several tiles wide would be used under the mallet, but the slight irregularity of the hand-made tiles didn’t call for it. We wiped off stray thinset from the faces of the tiles (lots on the first few, less as we got better at it). Step back. Admire. Now go to bed.

TILE MOUNTING (Part 2)

Time to remove the brace and begin the vertical legs. Same routine with thinset and then to the tiles. Line up the first row just below the bottom of the upper section, and work your way down. What? Wait! What’s going on?!? The tiles are sliding downward!!! Oh, yeah. Now I remember, the books, the videos said “Start from the bottom, work up”. Now we see why. Gravity!

Pull the tiles, scrape off the thinset. Begin again at the bottom of the leg, with a flat spacer under the edge of the bottom tile, building with tile, spacer, tile, until they meet the upper section. Adjust the gaps, using spacers as wedges until the gaps are comfortably uniform. As discussed earlier, the layout resulted in a lucky positioning that didn’t require any tile cutting, a pretty unusual occurrence. If a partial tile had been needed, it would have been determined in advance, cut with a wetsaw and placed at the bottom.

The tiles on the inside of the vertical legs are bullnose. They are placed so that the inner edge will line up with the face of the return tiles that will be placed inside the firebox in a later session. Now do the other leg. (Is it getting easier or are we getting better?) Again, time to knock off to let the mortar dry. But clean up before retiring (uncured thinset comes off oh-so-much easier).

The last tiles to be set are the return tiles inside the front vertical edges of the firebox. Same routine as the legs, beginning with a spacer, tile, spacer, building from the bottom to the top. Again, luck (and a little tweaking on grout width) gave us full tiles with no cutting. Clean up, let dry overnight and pull all spacers. The tiling is done! (Not the project, just the tiles).

GROUTING

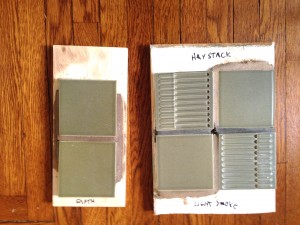

Next day, grouting begins. Huzzah! We knew exactly which grout color we wanted – Tobacco! So warm, so rich. But let’s mix up an actual sample. A few tiles on a board, grout around the edge. Uh, oh. The tiles are wrapped in fudge!? OK, the next color lighter, Earth!! Hmm. Still pretty muddy looking. Five days and four more colors on a sample board led us to the right complement color. Seeing the grout colors in reality, alongside actual tiles, is much more informative than a color chart. Given the cost of a tiling project, “wasting” a few tens of dollars on several bags of different colors of grout is a small investment to be sure you get a shade that you like. And once the grout is installed, it is cast in concrete.

One more step before the actual smear. The top edge of the upper horizontal row will get a grout line that will show below the upper molding. To keep that line on the same level as the rest of the grout, we installed a strip of furring level with the surface of the tiles.

Grout mixing and installation is like the books and videos say, but pay attention to the amount prepared at one time. Amateurs (like us) really should limit themselves to a small bucketful.

Mix, let slake, remix and apply. The pundits vary in their advice about consistency from thinner than mayonnaise (or even soupy) to thick peanut butter. Because of the wide joints, we leaned toward the stiffer end. Using a grout float, work it into the channels, scrape off, holding the float at nearly a 90 degree angle and on the diagonal. It really is a question of practice makes easier, if not perfect. The nice part is you can go back over the area a few times if the first pass is a bit ragged.

GROUT CLEANUP

Follow the grout’s instructions about waiting before wiping down with a sponge, and then do so gently. Aggressive will just undo the careful joints you have so lovingly created. You may need to finesse the ends of the joints, especially as they round toward the firebox returns and the decorative corners.

After wiping, wait the designated hours (as instructed on the grout bag, RTMS) to allow a good set before polishing the haze off with a soft cloth. You can gently tune up the edges of the tiles if the grout is still a bit high, but moisten the rag to avoid digging out too much.

You may need to do the grout process in several stages. It took us three sessions – one for the horizontal field and one for each of the vertical legs and their firebox returns.

With moldings reinstalled, the project is now just waiting for caulk, color-matched to the grout at the base, grout sealing, and the first blazing fire.

Filed under Projects Uncategorized

Tagged: grout, Renovation, tile, tiling

Great stuff! Thanks for sharing!

That sure is some project you did there! The fire place looks great however so it’s totally worth it. I would much rather refurnish a fireplace myself than buy a completely new one. Thanks for the tips:)

-V

Great idea, doesn’t look half bad, thanks for sharing! 🙂

I’ve never thought of this approach before. This really looks cool and easy to do. Grout clean-up seems to be the biggest problem.

The decision to refurbish rather than completely replace the fireplace was a great idea – saving on cost, mess and disruption and maintaining the original character. Great work!

A marvellous example of restoration rather than replacement! In the “throwaway” age this renovation is a great example to all homeowners and builders.

A marvellous example of restoration rather than replacement! In the “throwaway” age this renovation is a great example to all homeowners and builders.

A very well written article with lots of explanation about the project. Great job!

The end product looks wonderful! Thanks for making this easy to follow 🙂